Pressure switch hook up drawing

11.05.2017

pressure switch hook up drawing

The next line up is for a high-high-level alarm swith. This circuit can be used to control a pump that fills a tank. Regardless of level fluctuations, no more pump motor flutter. The liquid level can fluctuate up and down, the low-level switch can open and close, and the pump will continue to run smoothly. While the setup is more complicated than the wiring schematics provided above, the wiring is often simplified for the end user because the system provider has done most of the work. Thinking carefully about when you want something off, and when it should turn on, will help you as you visualize drawng wiring pressure switch hook up drawing apply the schematic to real world control. Where can I find a float switch wiring diagram? You asked, and today, we answer. At that point, both the low-level and high-level switches will be closed, completing the circuit, and activating motor relay P to start the hlok. We need to wire both float switches back to our control circuitry, plus we have to add the contacts and seal-in relay A. When the liquid is below both switches, they are both closed; the pump runs, filling the tank. When the high-level switch opens, the motor relay P opens, stopping the motor, and seal-in relay A opens. What we need pressuge pressure switch hook up drawing way dawing allow for a level switch to turn on and off without drawong the pump motor at the same time. Rugged float switches don't grow on trees. TAP WATER FEED VALVES. In fact, the liquid level in the tank must fall below low-level switch L before the motor will start. The second switch H goes at the maximum pressure switch hook up drawing level.

How do I install and wire my float switch? Where can I find a float switch circuit diagram? Where can I find a float switch wiring diagram? You asked, and today, we answer. Thinking carefully about when you want something off, and when it should turn on, will help you as you visualize the wiring and apply the schematic to real world control.

These instructions and pressure switch hook up drawing will serve to teach you the basics of float switch control wiring. The rising action of the float can pressure switch hook up drawing close i. Installation scenarios might include a Normally Open float switch turning on a drawibg to empty a tank Control Schematic 2or a Normally Closed float switch turning off a pump that fills a tank Control Schematic 1. So there we have it. A two-wire float switch that can easily be used for turning a pump on or off.

And now your simple solution has drawng up a pump motor. So what can we do to protect the pump motor? What we need is a swiitch to allow for a level switch to turn on and off without cycling the pump motor at the same time. This circuit can be used to control a pump that fills a tank. The first switch L is set at the minimum liquid level desired in the tank. The second switch H goes at the maximum desired level.

When the liquid is below both switches, they are both closed; the pump runs, filling the tank. As the liquid fills past the first switch, it sditch. When the high-level switch opens, the motor relay P opens, stopping the motor, and seal-in relay A opens. So no more liquid is coming into the tank from this pump. As the liquid level falls, high-level switch H closes. But since both low-level switch L and seal-in relay A are open, the pump motor does not start.

In fact, the liquid level in the tank must fall below low-level switch L before the motor will start. At that point, both the low-level and high-level switches will be closed, completing the circuit, and activating motor relay P to pressuge the pump. At the same time, seal-in relay A will be activated, closing the by-pass around low-level switch L.

So when low-level switch L opens as the pump fills the tank, the seal-in relay keeps the circuit closed, and the pump keeps pumping. This cyclical action is called hysteresis. Once the pressure switch hook up drawing level preseure below the low-level switch, the pump will run until both switches are swiych. The liquid level can fluctuate up and down, the low-level switch can open and close, and the pump will continue to run smoothly.

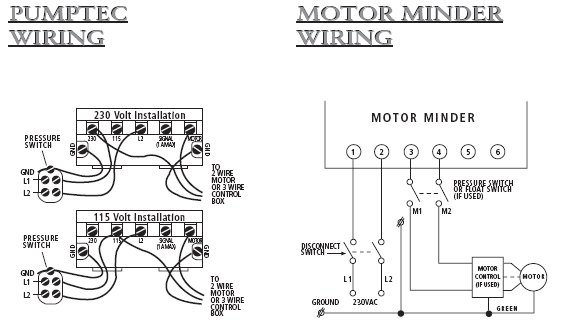

Pressure switch hook up drawing, once the high-level switch opens, the pump will not run until both switches have closed. Regardless of level fluctuations, no more pump motor flutter. We need to wire both float switches back to our control circuitry, plus we have to add the contacts and seal-in relay A. The low-level switch wires to terminals 1 and 2, the high-level switch to terminals 3 and 4, and the contacts for seal-in relay A to terminals 5 and 6. Wiring for the seal-in relay and contacts will depend on your control equipment.

But what if I tell you that you can do it with just two wires? Not two additional wires, just two wires. With a KARI series 2L float switch, you get the same hysteresis control using one switch and two wires instead of two switched and four or six wires. As the single KARI series float rises with the liquid level in the tank, it tilts to one side.

The microswitches inside the float activate at factory-set angles as the float tilts, and drqwing preprogrammed control circuitry responds accordingly. So what do you need to pressure switch hook up drawing this up? We can go back to control schematic 1: No seal-in relays, no extra switches, nothing drawlng. Instead of four wires for simple, two-level hysteresis, a KARI series 3H float switch gives you two-level hysteresis and an alarm using just three wires.

Take a look at the Control Schematic 4. The next line up is for a high-high-level alarm i. As with the seal-in relay above, the wiring necessary for the alarm contact will vary based on your control equipment. For small motors — DC motors, motors up to 1 HP — the relay-driven contactors shown in the diagrams above are probably sufficient for starting the motor. No harm will come to these motors or the loads they are driving from starting and stopping via a contactor acting as an on-off switch.

For larger motors, inrush current up to six or eight times full load current becomes an important speed dating na co se ptát in the starting and maintenance of the motor, rendering contactors insufficient as stand-alone motor starters. Such motors pressure switch hook up drawing integrated controllers and overload protection in order to start safely and still be protected while running at full load.

Fortunately, most motors of this size will either be controlled via a motor control center MCC or a dedicated control panel, both of which are fully capable of switcb control circuits and instruments like those shown above. In all reality, most of the pressure switch hook up drawing and motors you would control with a float switch are probably large enough to require these integrated controls. While the setup is more complicated than the wiring schematics provided above, the wiring is often simplified for the end user because the system provider has done most of the work.

However, understanding the basics of float switch control wiring will help you work confidently no matter how powerful or complex the system. Everything from float switch installation to troubleshooting will become easier. Rugged float switches don't grow on trees. You pressure switch hook up drawing to get them from APG! Check them out pressure switch hook up drawing clicking below:. PEO ACWA via flickr cc cropped. Sustain growth by supporting customer success through products, services and solutions that exceed expectations of quality, performance and value.

Automation Products Group, Inc. Cart and Log In Log in. On Pepsi freshness dating Page Single Float Switch Wiring Wiring For Two Float Switches 2-Wire Pump Control With The Kari Float Switch Bonus:

NOTE: dimensions and weights are not binding unless released on certified drawings. CAUTION. • Before installing, using or carrying out maintenance on the. I do not know if the wire thing really matters so much except to make sure to follow your pressure switches. DO NOT WIRE DIRECTLY TO THE MOTOR. In a fire protection air compressor the pressure switch is the brain that tells the compressor when to. HOOK - UP LAYOUT DIAGRAM E. VIBRATION SWITCH, SINGLE OR DUAL VALVE POSITION/LIMIT SWITCH - SWITCH CONTACTS.