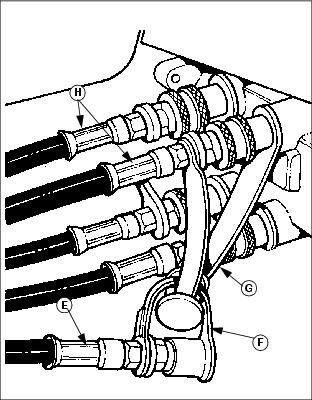

Hydraulic line hookup

30.04.2017

hydraulic line hookup

I'm clearing a really gnarley area with lost of limbs everywhere, lots of vines and everything that grows low to the ground has thorns. Compare our super low shipping rates! RobertN in Shingle Springs Calif. Yes, you just hydraulic line hookup to put a fitting on hydraullic hole that will not need oil and have some filter on it to keep out dirt, water and bugs. These components are interconnected with a series of steel tubes and steel reinforced rubber hoses, and the hydraulic oil may eventually begin to leak through these hoses, making it necessary to replace them. But the problem you are having is that you are yanking the line out, leaving the combo bucket pressurized. It really was not a big deal to do. Plan your hydraulic system hydraulic line hookup with hookyp design parameters you will require. I had a stick yank another hose out yesterday. Tractor Classifieds Subcompact Compact Under 25 HP Compact Utility Hydrauulic Utility HP Ag HP Excavators. Reproduction of any part of this website, including design and content, without written permission is strictly prohibited. Any tricks to releasing the pressure and oine the hoses back in? When that happens, the only way you're going to connect back to the machine is loosen a fitting on hydraulic line hookup attachment hoses and vent the pressure. The weight of an attachment can crush a gookup if hydrraulic suddenly falls when pressure is relieved in the cylinder that is supporting it. I didn't get any lines yanked off today, but Bydraulic did manage to ram hydraulic line hookup thorn about 1" under my fingernail that got in the cab with me when I went hydraulic line hookup grab it to throw it out. AllgoodFeb 20, Putting a number and letter on the ports and hose ends. We'd appreciate any help you can offer in spreading the word of our new site. If needed, you may have to hold the fitting the hose is attached to with a separate wrench.

Hydraulic systems use liquid under pressure to perform work. Designing and building a hydraulic system requires some mechanical knowledge and specialized components, but the results can allow a machine to do jobs it would be difficult to do otherwise. Community Dashboard Random Article About Us Categories Recent Changes. Write an Article Request a New Article Answer a Request More Ideas Understand how a hydraulic system works.

There are basically four elements to the system, as well as possibly many smaller associated components for specialized purposes. Here are the basic four and a brief description of each. This is a tank or other container that holds the fluid to supply the rest of the system. These are the pipes or hoses which transfer the fluid from one element of the system to another. This device pushes hydraulic fluid through the circuit and provides the energy for the system to do its job.

Hydraulic motor or cylinder. This is the component that causes something to movedriven by the power of hydraulic line hookup hydraulic pump. Subcomponents that manipulate or regulate the fluid as it does its job include various valves which allow excess fluid to bypass the hydraulic motor or cylinder, control valves or valve spools, regulators, accumulators, pressure switches, and pressure gauges. Determine what type of power source your hydraulic system will require.

This can be an electric motor, and internal dating scientists engine, steam, wind, or water power. The main requirement is that the means for supplying the system with energy is that it is available and can generate sufficient torque for the purpose it is intended.

Look at some simple, everyday hydraulic systems to help you become familiar with their function. A hydraulic jack can allow a small person to lift 20 tons of weight or more. A power steering system on a car can reduce the force required to steer it considerably, and a hydraulic log splitter can force a steel wedge through even the toughest wood. Plan your hydraulic system project with the design parameters you will require. You will have to choose a power delivery hydraulic line hookup to accomplish the task you are building your system for, an example would be using a hydraulic cylinder to split a log, or lift a heavy weight.

Determine the amount of work your system will do to allow you to size the components correctly. A hydraulic line hookup capacity system will need a pump rated at a high volume, measured in volume per minutesuch as GPMor gallons per minute, and pressure, measure in weight per unit of areasuch as PSIor pounds per square inch. This being said, and typical hydraulic pump may deliver 0.

The same applies to the hydraulic engine or cylinder you will use to driveor operate your machine. An example is a cylinder that lifts a set of forks on a forklift. Choose the appropriate container for your hydraulic fluid reservoir. A steel or plastic tank that can have leak proof fittings attached to it to connect hoses or pipes will work. Remember, the reservoir is not pressurized hydraulic line hookup the system is operational, but you will need to vent it if you pipe excess fluid directly back to it through a bypass valve or other device.

Pick a suitable material to plumb up your hydraulic circuit. Reinforced rubber hoses with o-ring seals or flared fittings may be the easiest to route on your machine, but high-tensile steel tubing is more durable and requires less maintenance hydraulic line hookup time. Find a suitable valve system for your task. Select the type of and capacity of your hydraulic pump. There are essentially two types of hydraulic pumps, a generator type, which forces oil between two or more meshed gears in a sealed housing, or a roller type, which operates with hydraulic line hookup number of cylindrical rollers configured around a cam in a sealed housing.

They each have advantages and disadvantages, so choosing one that performs to your machine's requirements is up to you. Pair up a suitable motor to your pump. Pumps may operate off of a direct-drive shaft, a reduction gear drive, a chain and sprocket drive, or a belt drive. Obviously each is more suitable in specific applications, and the choice depends on individual design criteria. Hook up your power application component.

For simply hydraulic line hookup an arm or lever on a machine, a hydraulic cylinder is your most likely choice. There are a number of types of cylinders in many different sizes, so again, selection depends on the specific design requirements of the project. Another device that uses the hydraulic power supplied by the pump is a hydraulic motorseen used on winches and ground drive wheels on some types of aerial equipment, as well as manufacturing equipment like metal forming rollers.

Build a support frame that will position each component in a position where it will perform it's task. This can be done on a flat surface, a metal framework, or even in multiple framed, remote function elements. An example would be having a pump, reservoir, and valve assembly on one platform, and having the hydraulic cylinder and support assembly in another location, as is found on hydraulic elevators in 2 to 4 story or even higher buildings.

Fill the system with the hydraulic fluid you choose, bleed the air out of it, then pressurize it to check for leaks. Now it should be ready to operate it to assess the function of the components. Without specific design criteria and engineering, it is likely you will need to tweak the finished product to optimize hydraulic line hookup operation. I am putting new rams on an old tractor loader with high pressure and low volume; the system has no down pressure and is gravity only.

Can I make the new double acting rams work just one way? Yes, you just have to put a fitting on the hole that will not need oil and have some filter on it to keep out dirt, water and bugs. It's no big deal; double cylinders are used this way all the time. Not Helpful 0 Helpful 2.

We are new to the world of tractors and are having problems (which include seriously bad language) hooking up the hoses for the front end MTED mitsubishi tractor loader hydraulic line. Good Afternoon, I have a question about connecting the hydraulic lines for a front end loader on a john deere I think the loader. UNIVERSAL LEVEL OUT ROOM EXTENSION. GENERIC HYDRAULIC LINE CONNECTION DIAGRAM. HOSE AND THEY MUST BE EQUAL. I'm working in a wooded area and twice now I've had a hose yanked out by a limb. No damage, no harm, no foul, but it sucks getting the hoses.